ABOUT US

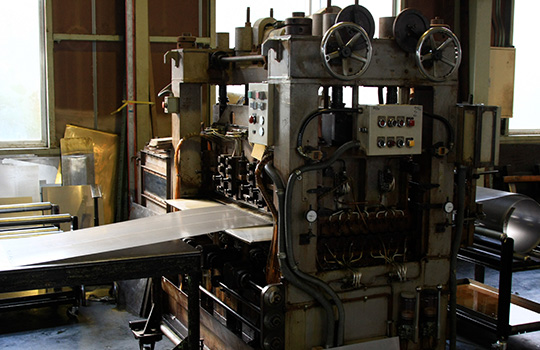

Equipment to Facilitate Craftsmanship

Our factory is equipped to facilitate the craftsmanship required to manufacture truly high-performance, high-precision perforated screens, as well as processes like welding, profiling, and lasering.

Designing Our Own Equipment

From basic dies to production equipment, everything to do with our presses are designed in-house here at Nunobiki Manufacturing. We are also fully equipped to cut, weld, bend, profile, laser, or otherwise process materials to meet your specific needs.

Main production equipment

-

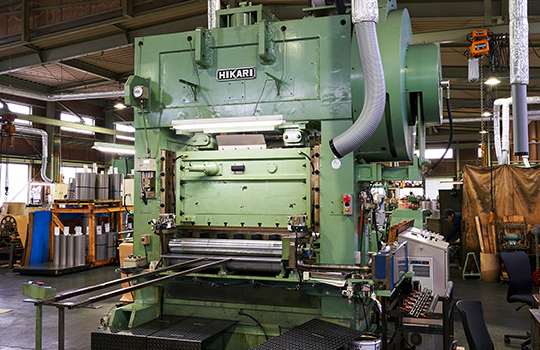

High-speed automatic punching press

– Futami Factory●Tonnage capacity 300t

●Max. working width 1250mm

-

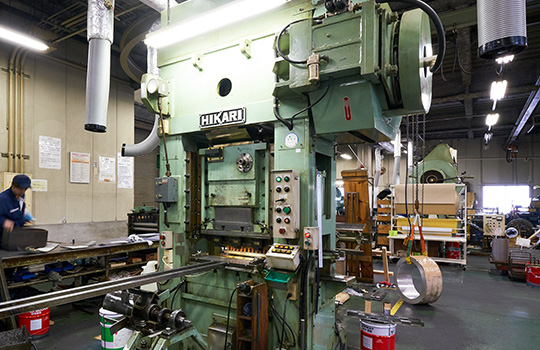

High-speed automatic punching press

– Futami Factory●Tonnage capacity 100t

●Max. working width 500mm

-

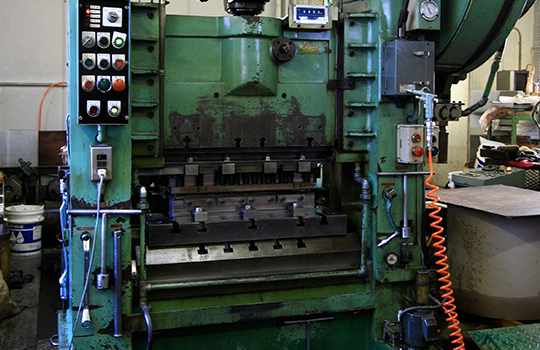

Precision press for special profile

– Headquarters Factory●Tonnage capacity 300t

●Max. working width 1250mm

-

Expanded metal machine

– Headquarters Factory●Max. working width 1000mm x 1

●Max. working width 600mm x 1

-

Fast automatic punching press

– Futami Factory●Tonnage capacity 200t

●Max. working width 1250mm x 1 -

Fast automatic punching press

– Futami Factory●Tonnage capacity 100t

●Max. working width 650mm x 2 -

High-speed automatic punching press– Futami Factory

●Tonnage capacity 100t

●Max. working width 610mm x 1 -

Precision press for special profile

– Headquarters Factory●Tonnage capacity 10t

●Max. working width 1250mm×3000mm x 1

Die Machining Equipment

-

3D machining center

– Headquarters Factory●Max. working area 460mm×1025mm

-

Benchtop precision drill

– Headquarters Factory●10machines

-

Electric discharge machines

– Headquarters Factory● Wire ED machine x 1

● Die sinking ED machine x 2

● Fine hole ED machine x 1 -

Grinding machine

– Headquarters Factory● Surface grinding machine x 3

-

Other equipment

– Headquarters Factory● 3D milling machine x 1

Fabrication Equipment

-

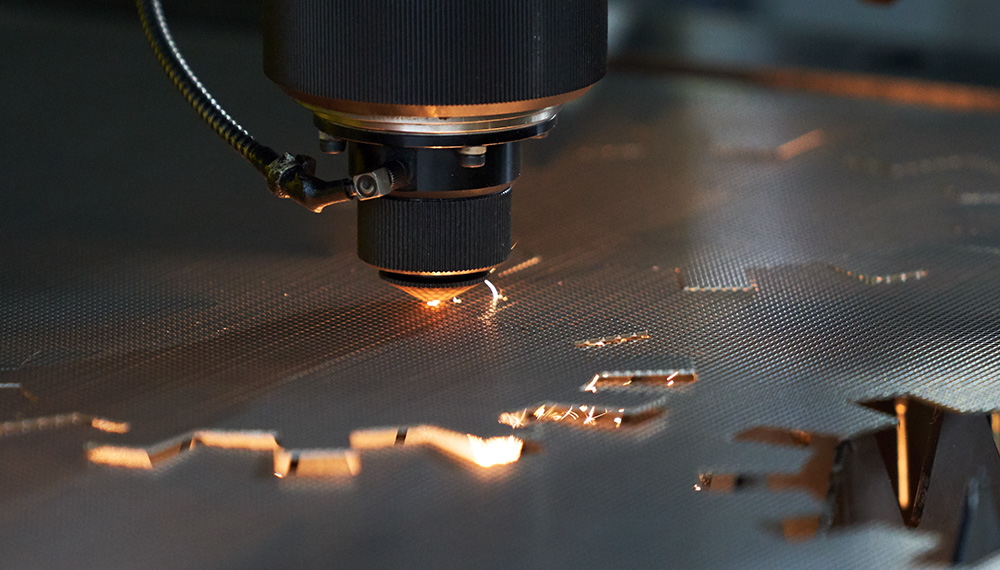

Laser cutter

– Headquarters Factory●Tonnage capacity 4KW 1550mm×3080mm

-

Finish leveler

– Futami Factory●Max. working width 1250mm

+Note

Stress distribution for punched products

-

Press break

– Headquarters Factory●Tonnage capacity 55ton

●Max. working width 1300mm

+Note

Product fabrication and shaping

-

Roll slitter

– Futami Factory●Max. working width 1250mm x 1

+Note

Material and product cut -

Roll slitter

– Headquarters Factory●Max. working width 650mm x 1

+Note

Material and product cut -

Welders

– Headquarters Factory● Seam welder x 1

● Spot welder x 1

● Twin-spot welder x 1

+Note

For product shaping and fabrication -

Bending roll

– Headquarters Factory● Max. working width 1250mm x 1

● Max. working width 1000mm x 1

● Max. working width 600mm x 3

+Note

Product fabrication and shaping -

Shearing

● Shearing machine – Futami Factory

Max. working width 1250mm x 2

● Shearing machine – Headquarters Factory

Max. working width 650mm x 1

Max. working width 2500mm x 1

+Note

Product fabrication and shaping -

Levelers

● Rough leveler – Futami Factory

Max. working width 2500mm x 1

● Rough leveler – Headquarters Factory, Futami Factory

Max. working width 650mm x 2

● Small finish leveler – Headquarters Factory

Max. working width 500mm x 2

+Note

Stress distribution for punched products

The small finish leveler is used for thin sheets. -

Other equipment

● Auto-sizing cutter – Futami Factory

Max. working width 600mm x 1

● Rolling mill – Headquarters Factory

Max. working width 500mm x 1

● Belt sander grinder – Headquarters Factory

Max. working width 520mm x 1

● Power press – Headquarters Factory

Tonnage capacity 20t x 2

+Note

Sized cutting, product straightening, special grinding, Product fabrication and shaping